product model: IC693ACC317 Connector Kit, Crimp Type

product description: The IC693ACC317 Connector Kit, Crimp Type by GE is a reliable crimp-type connector kit designed for secure electrical connections in industrial automation systems. It ensures durable and efficient wiring for PLCs and control modules.

brand: GE

country of origin: United States

net weight: 0.2 lbs

dimensions: 4.5 x 2.5 x 1 inches

power supply: N/A (passive component)

input/output: Compatible with standard PLC I/O modules

communication interface: N/A (hardware connector)

usage: Ideal for industrial automation, machinery control, and PLC systems. For more details, visit GE’s official website or contact us for support.

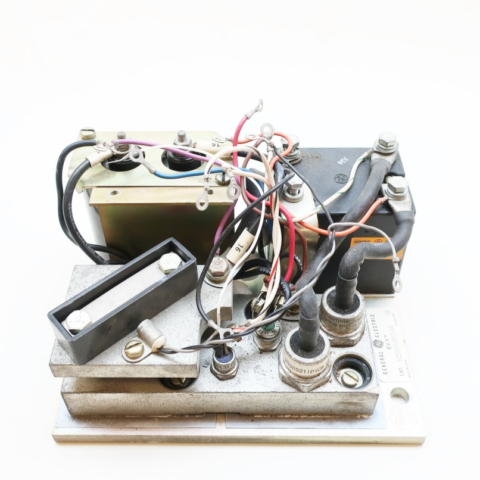

GE IC693ACC317 Connector Kit, Crimp Type

$44,225.00

Upgrade your industrial connectivity with the GE IC693ACC317 Connector Kit, Crimp Type—a reliable solution for secure and efficient wiring. Designed for durability, this crimp-type connector ensures a strong, vibration-resistant connection, perfect for demanding environments. Simplify installations and reduce downtime with its user-friendly design. Backed by a one-year warranty, you can trust GE’s quality and performance. Don’t miss out—enhance your setup today! Order now and experience seamless connectivity!

| Product Model | IC693ACC317 |

|---|---|

| Product Description | The IC693ACC317 is a high-performance battery backup module designed to provide reliable power to GEs Series 90-30 programmable logic controllers PLCs, ensuring data retention during power outages and facilitating seamless operation. |

| Brand | GE |

| Origin | USA |

| Net Weight | 1.5 lbs 0.68 kg |

| Dimensions | 4.5 in x 3.5 in x 1.5 in 11.43 cm x 8.89 cm x 3.81 cm |

| Power Supply | 3.6V Lithium battery |

| Input/Output | Designed for connection to Series 90-30 PLC systems, typically supports 8 discrete inputs and 8 discrete outputs. |

| Communication Interface | Compatible with GEs proprietary communication protocols, including Ethernet and Serial communication. |

| Use | Commonly used in industrial automation, process control, and manufacturing environments to maintain PLC functionality and data integrity during power failures. |

There are no reviews yet.