product_model: F650 Feeder Protection, Digital Bay Controller

product_description: The GE F650 Feeder Protection, Digital Bay Controller is a high-performance protection and control device designed for electrical substations, offering advanced feeder protection, automation, and monitoring capabilities.

brand: GE

country_of_origin: USA

net_weight: 8.5 kg

dimensions: 300 mm x 200 mm x 100 mm

power_supply: 24-250 V DC / 100-240 V AC

input_output: 16 digital inputs, 8 relay outputs, 4 analog inputs

communication_interface: Ethernet, RS485, IEC 61850, Modbus

usage: Ideal for utility substations, industrial power systems, and renewable energy applications, the F650 ensures reliable feeder protection and bay control. For more details, visit GE’s official website or contact us for support.

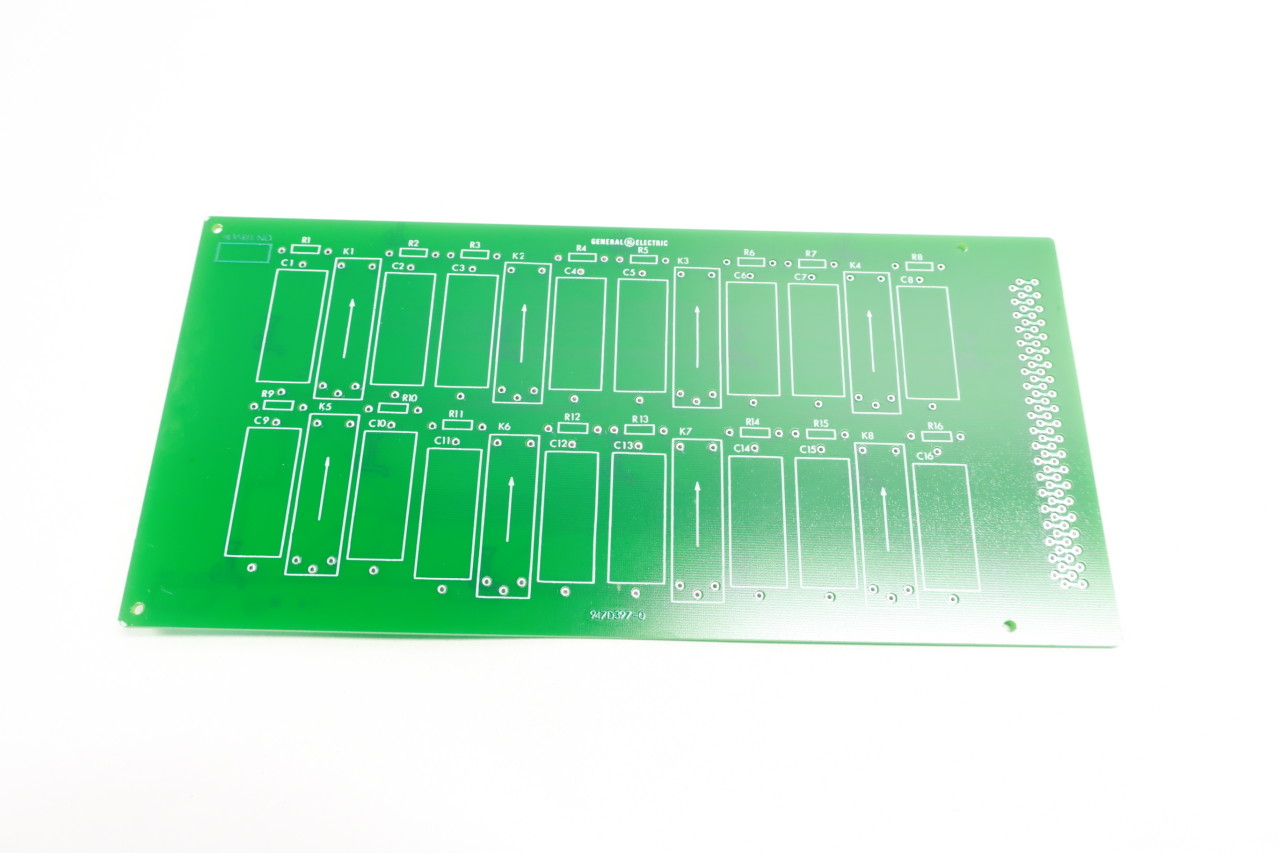

GE F650 Feeder Protection, Digital Bay Controller

$88,481.00

GE F650 Feeder Protection & Digital Bay Controller delivers advanced protection, control, and monitoring for electrical substations. Featuring high-speed fault detection, customizable logic, and seamless integration with smart grids, this robust solution ensures reliability and efficiency. Its user-friendly interface simplifies operation, while rugged design guarantees durability in harsh environments.

Enjoy peace of mind with a one-year warranty, ensuring top-tier performance and support. Upgrade your power system with GE’s trusted technology today!

Order now to enhance your grid’s safety and performance!

| Product Model | F650 |

|---|---|

| Product Description | The GE F650 is a versatile programmable logic controller PLC designed for efficient automation and control in industrial environments. It offers advanced processing capabilities and robust functionalities to streamline operations and enhance productivity. |

| Brand | GE |

| Origin | United States |

| Net Weight | 2.5 kg |

| Dimensions | 200 mm x 150 mm x 100 mm |

| Power Supply | 24V DC, 3A |

| Input/Output | 16 digital inputs, 16 digital outputs, 4 analog inputs, 2 analog outputs |

| Communication Interface | Ethernet/IP, RS-232, RS-485 |

| Use | Typical applications include manufacturing processes, machine control, assembly lines, and other automated systems requiring reliable and precise control solutions. |

There are no reviews yet.