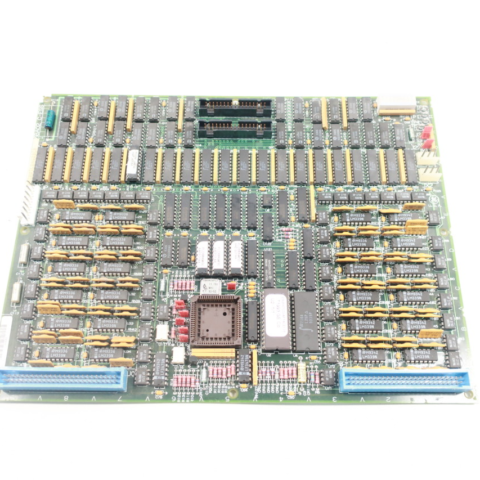

product model: 850-EP Feeder Protection System

product description: The 850-EP Feeder Protection System by GE is a robust and reliable solution designed to safeguard electrical feeders against faults, ensuring stable power distribution. It offers advanced protection features, real-time monitoring, and seamless integration with power networks.

brand: GE

country of origin: United States

net weight: 15 kg

dimensions: 400 x 300 x 200 mm (W x H x D)

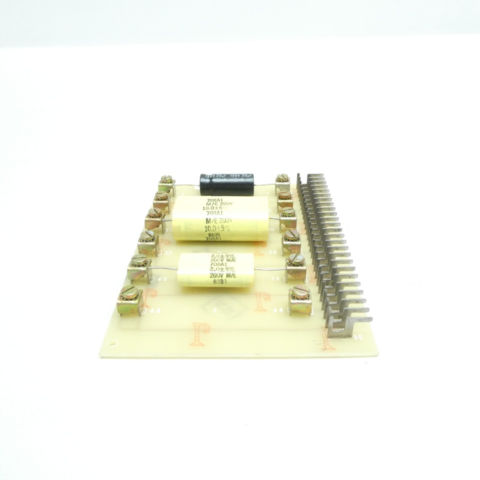

power supply: 24-48 VDC, 100-240 VAC

input/output: 6 analog inputs, 8 digital inputs, 4 relay outputs

communication interface: Ethernet, RS-485, IEC 61850 protocol

usage: Ideal for industrial power systems, substations, and utility grids. For more details, visit GE’s official website or contact us for support.

GE 850-EP Feeder Protection System

原价为:$28,524.00。$22,539.00当前价格为:$22,539.00。

Upgrade your power distribution with the GE 850-EP Feeder Protection System—a reliable solution designed to safeguard electrical networks. Featuring advanced fault detection, customizable settings, and seamless integration, this system ensures optimal performance and minimal downtime. Its user-friendly interface and robust design make it ideal for industrial and utility applications. Backed by a one-year warranty, you can trust GE’s quality and support. Don’t miss out on enhanced protection and efficiency—order now to secure your power infrastructure today!

| Product Model | 850-EP |

|---|---|

| Product Description | The GE 850-EP is a robust and versatile programmable logic controller PLC designed for demanding industrial applications. It features advanced processing capabilities, ensuring high-speed data processing and control for various automation tasks. With its modular architecture, the 850-EP allows for easy scalability and integration into existing systems, making it ideal for complex automation projects. |

| Brand | GE |

| Origin | United States |

| Net Weight | 2.5 kg |

| Dimensions | 250 mm x 150 mm x 70 mm |

| Power Supply | 24 V DC, 10 tolerance |

| Input/Output | 16 digital inputs, 16 digital outputs, 4 analog input channels, 4 analog output channels |

| Communication Interface | Ethernet/IP, Modbus TCP/IP, RS-232, RS-485 |

| Use | Commonly used in manufacturing, process control, and equipment automation, particularly in industries such as automotive, food and beverage, and pharmaceuticals. |

There are no reviews yet.