GE CR224

The Importance of the GE CR224 in Electrical Engineering and Industrial Automation

Welcome to the AE Automation Auto Parts blog, where we delve into the critical components of automotive and industrial automation. Today, we focus on the GE CR224, a vital part of electrical engineering that plays a significant role in enhancing the efficiency and reliability of various industrial processes.

What is the GE CR224?

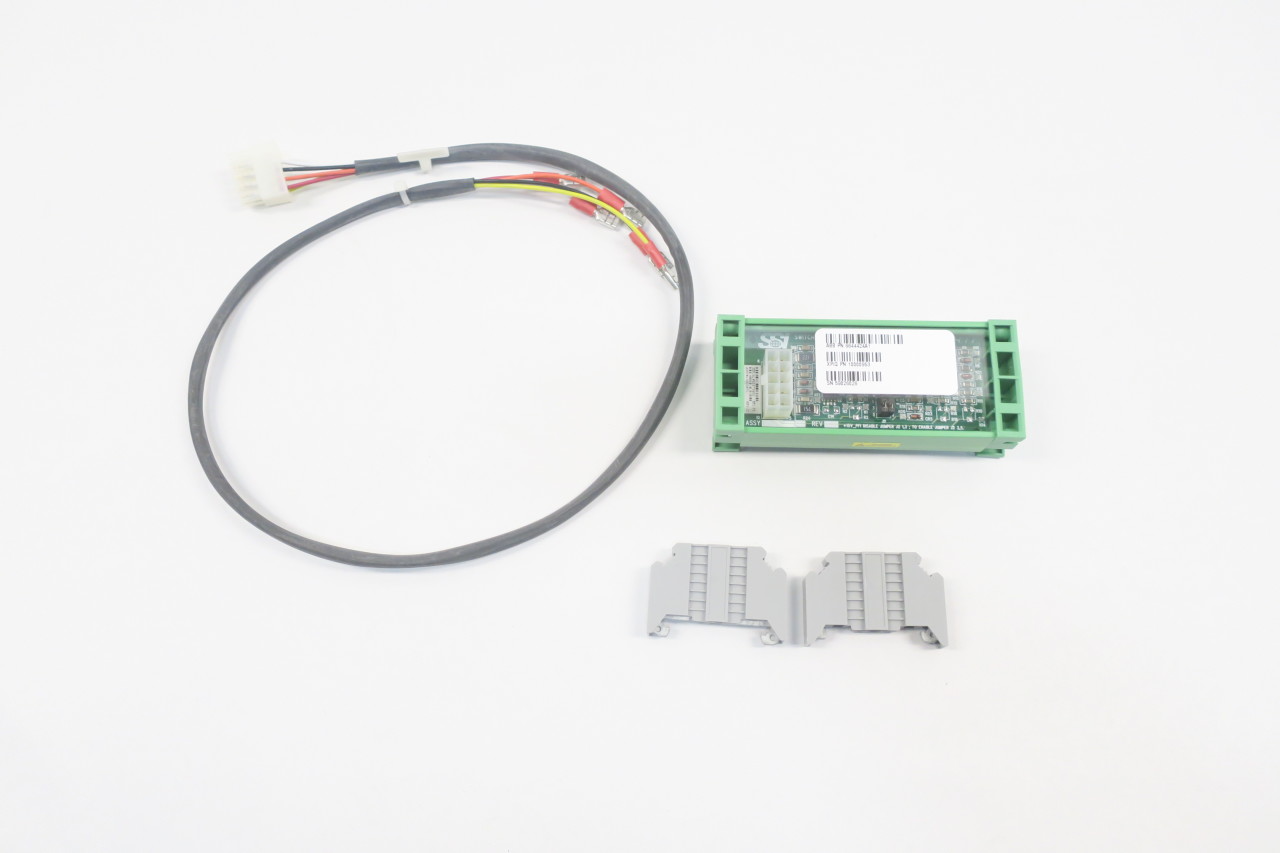

The GE CR224 is an advanced contactor designed for industrial applications. Known for its robustness and reliability, this component is essential in controlling and automating electrical power. The GE CR224 features a compact design, making it suitable for applications where space is limited while still providing exceptional performance.

Electrical Engineering Importance

In the realm of electrical engineering, the GE CR224 serves as a critical interface between electrical circuits and loads. Its ability to handle high power loads while ensuring safety and efficiency is paramount. The GE CR224 adheres to the IEC 60947-2 standard, which governs low-voltage switchgear and control gear. This compliance signifies that the contactor meets international safety and performance criteria, making it a trusted choice for engineers and technicians in the field.

Technical Specifications (IEC 60947-2)

Understanding the technical specifications of the GE CR224 is crucial for its effective application. Here are some of the key specifications:

- Rated Operational Voltage: Up to 690V AC

- Rated Operational Current: 25A to 40A, depending on the model

- Utilization Category: AC-3 and AC-4 for motors

- Frequency: 50/60 Hz

- Mechanical Life: Over 10 million operations

- Electrical Life: Up to 1 million operations under rated conditions

These specifications highlight the GE CR224’s capability to operate reliably in demanding industrial environments, ensuring it is a popular choice among electrical engineers.

Applications in Industrial Automation

The applications of the GE CR224 are extensive, particularly in industrial automation and renewable energy sectors. Here are some common applications:

- Motor Control: The CR224 is extensively used in controlling electric motors, providing reliable starting and stopping functionalities.

- Automation Systems: It is a vital component of automated systems, allowing for the efficient management of machinery and equipment.

- Renewable Energy: In renewable energy systems, such as solar and wind, the GE CR224 helps manage the electrical loads, ensuring optimal performance and safety.

- HVAC Systems: The contactor is also used in heating, ventilation, and air conditioning systems to control the motors that drive fans and compressors.

These applications illustrate the versatility and importance of the GE CR224 in enhancing operational efficiency and safety in various industrial contexts.

Conclusion

The GE CR224 is more than just a component; it is a cornerstone of modern electrical engineering and industrial automation. Its adherence to IEC 60947-2 standards ensures that it meets global safety and performance expectations, making it a reliable choice for engineers worldwide.

For more information on industrial automation components, be sure to visit our website or check out the IEC website for detailed technical insights.