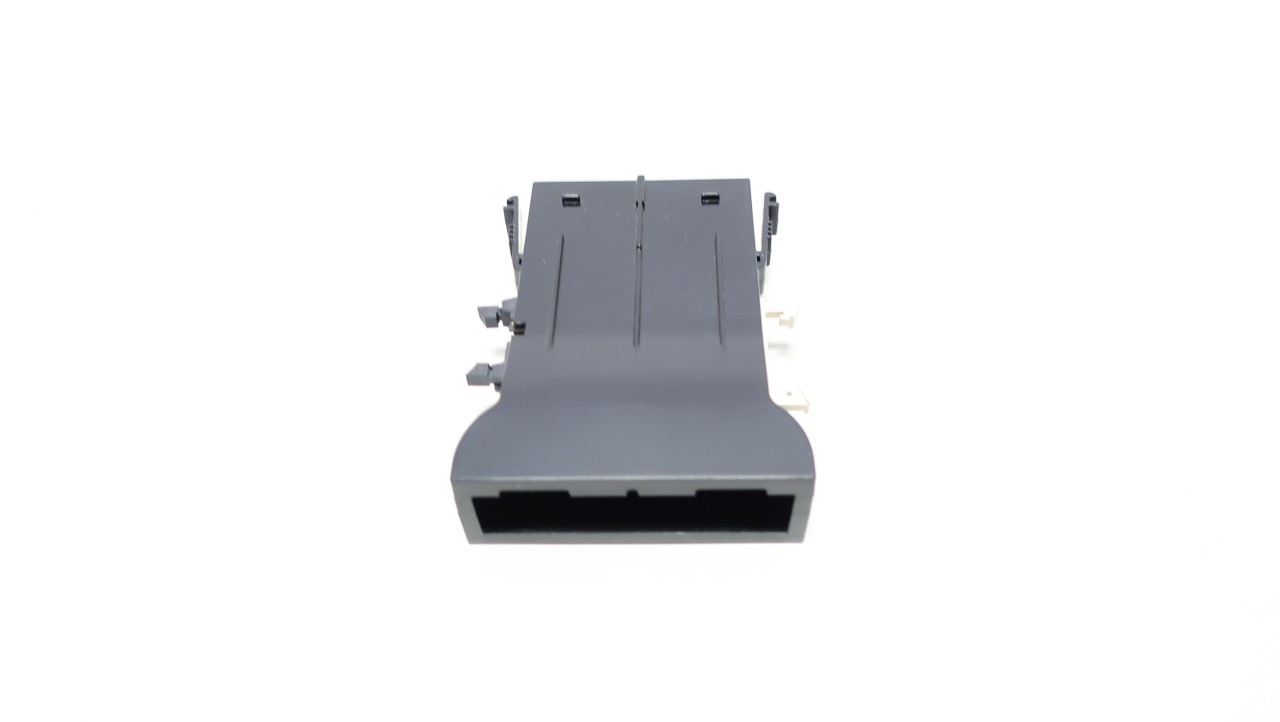

YOKOGAWA NFCP100-S00 S3

Understanding the YOKOGAWA NFCP100-S00 S3: A Key Component in Industrial Automation

At AE Automation Auto Parts, we focus on providing top-quality automotive and industrial automation components. One such component that stands out in the field of electrical engineering is the YOKOGAWA NFCP100-S00 S3. This device is not only essential for ensuring efficient operations in industrial settings but also plays a significant role in the growing renewable energy sector.

The Importance of Electrical Engineering

Electrical engineering is a fundamental discipline that combines knowledge of electrical systems with innovative technology to create solutions for various industrial challenges. The importance of devices like the YOKOGAWA NFCP100-S00 S3 cannot be overstated, as they ensure reliable performance, safety, and efficiency in automation processes. As industries evolve, the demand for robust electrical components continues to rise, making it crucial for engineers to incorporate high-quality products into their designs.

Technical Specifications: IEC60947-2 Compliance

The YOKOGAWA NFCP100-S00 S3 adheres to international standards, particularly IEC60947-2, which governs the performance and safety of low-voltage switchgear and control gear. Here are some key specifications:

- Rated Operational Voltage: Up to 690V

- Rated Operational Current: 100A

- Short Circuit Protection: Ensures safety and reliability in electrical circuits

- Temperature Range: Operates efficiently in a variety of environmental conditions

- Durability: Designed for a long service life with minimal maintenance

Meeting IEC60947-2 standards guarantees that the NFCP100-S00 S3 provides both performance and safety, which are critical in industrial applications.

Applications in Industrial Automation

The YOKOGAWA NFCP100-S00 S3 is widely used in various industrial automation applications. Its versatility makes it suitable for:

- Process Control: Essential in manufacturing plants to ensure smooth operational flow.

- Machine Automation: Integrates seamlessly with other automation components to enhance productivity.

- Energy Management Systems: Plays a vital role in monitoring and managing energy consumption.

By using the NFCP100-S00 S3, industries can improve their overall efficiency and reduce downtime, leading to increased profitability.

Renewable Energy Applications

As the world shifts towards sustainable energy solutions, the YOKOGAWA NFCP100-S00 S3 has found its place in various renewable energy applications. It is particularly useful in:

- Solar Power Systems: Helps in managing power distribution and ensuring safe operation.

- Wind Energy Systems: Provides reliable control and monitoring for wind turbines.

- Energy Storage Solutions: Vital for balancing energy supply and demand in battery storage systems.

With the increasing emphasis on green technologies, components like the NFCP100-S00 S3 are becoming essential in the design and implementation of renewable energy systems.

Conclusion

The YOKOGAWA NFCP100-S00 S3 is more than just a component; it is a critical part of the industrial automation and renewable energy landscape. By adhering to the high standards set by IEC60947-2, it ensures safety, reliability, and efficiency in various applications. At AE Automation Auto Parts, we are committed to providing components that help drive innovation in automation and energy management. To learn more about our offerings, visit us at fanucautoparts.com.

For further insights into electrical engineering standards and practices, check out the International Electrotechnical Commission (IEC).