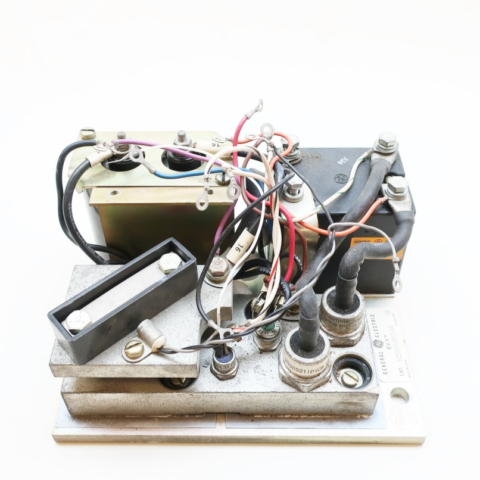

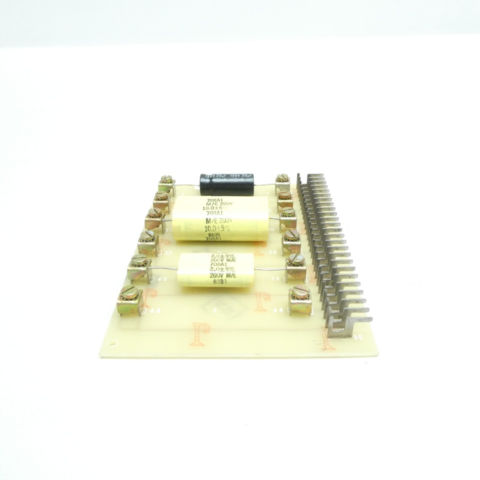

Product model: LM10 motor protection system

Product description: The GE LM10 motor protection system is a reliable solution designed to safeguard motors against overloads, phase loss, and other electrical faults, ensuring optimal performance and longevity.

Brand: GE

Country of origin: USA

Net weight: 2.5 kg

Dimensions: 150 mm x 100 mm x 50 mm

Power supply: 24V DC, 110-240V AC

Input/output: 3-phase current input, relay output for fault signaling

Communication interface: Modbus RTU, RS-485

Usage: Ideal for industrial motor protection in manufacturing, HVAC, and automation systems. Learn more about GE products here or contact us for support.

GE LM10 motor protection system

原价为:$24,345.00。$9,679.00当前价格为:$9,679.00。

GE LM10 Motor Protection System – Safeguard your motors with precision and reliability! This advanced system offers real-time monitoring, overload protection, and fault detection, ensuring optimal performance and extended equipment life. Designed for industrial applications, the LM10 delivers seamless integration and user-friendly operation.

Enjoy peace of mind with a one-year warranty, backed by GE’s trusted quality. Don’t let motor failures disrupt your operations—upgrade to the LM10 today!

Order now and experience unmatched protection and efficiency!

| Product Model | LM10 |

|---|---|

| Product Description | The GE LM10 is a versatile industrial automation controller designed for real-time process control and monitoring in various manufacturing environments. It offers robust performance and scalability, enabling seamless integration into existing systems for optimized productivity. |

| Brand | GE |

| Origin | United States |

| Net Weight | 2.5 kg |

| Dimensions | 250 mm x 150 mm x 100 mm |

| Power Supply | 24 V DC, 1 A |

| Input/Output | 16 Digital Inputs, 16 Digital Outputs, 4 Analog Inputs 0-10V, 4 Analog Outputs 0-10V |

| Communication Interface | Ethernet, RS-232, RS-485, USB |

| Use | Ideal for applications in manufacturing, process control, packaging, and material handling systems, where efficient automation and real-time data processing are essential. |

There are no reviews yet.